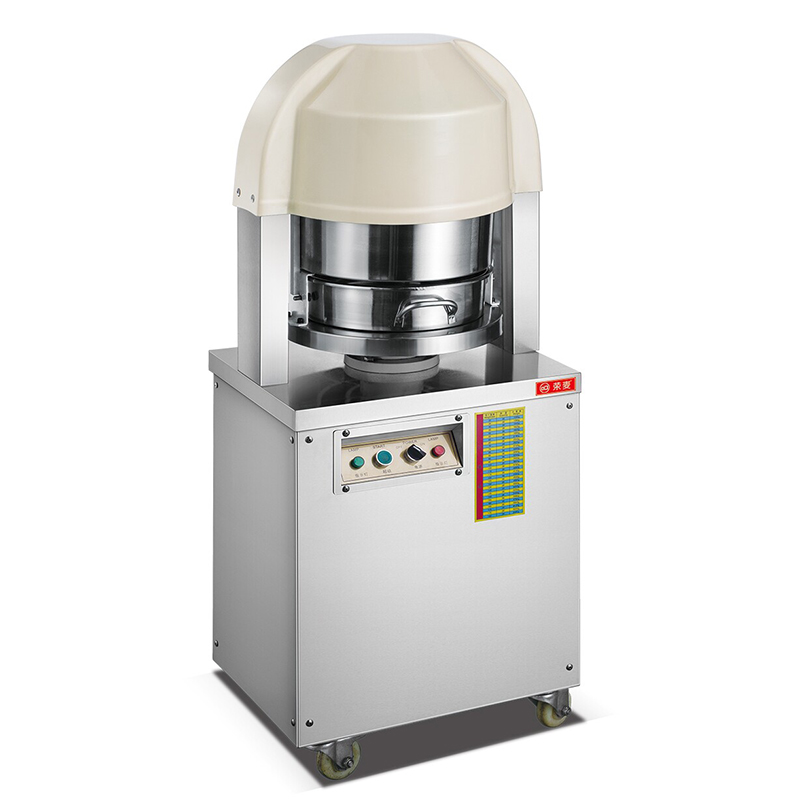

Semi Automatic Dough Divider Rounder Dough Ball Rounder Making Machine

R&M semi automatic dough divider rounder can use as pizza dough rounder machine,bread rounder machine as well as bun rounder. it will be your sincere and best assistant in your bakery shop business.

Semi automatic dough ball making machine

About R&M semi automatic dough ball making machine

R&M semi automatic dough divider rounder can use as pizza dough rounder machine,bread rounder machine as well as bun rounder. it will be your sincere and best assistant in your bakery shop business.

Specification of dough ball rounder machine

| Model | TYPE | Voltage | Power (kw) | Specification | Size (mm) | N.W.(KG) |

| RMG-26S | SEMI-AUTO | 220V/380V | 0.75 | 26 粒 pcs / 50-140g | 670x780x1492 | 310 |

| RMG-30S | 220V/380V | 0.75 | 30 粒 pcs / 30-100g | 670x780x1492 | 310 | |

| RMG-36S | 220V/380V | 0.75 | 36 粒 pcs / 20-80g | 670x780x1492 | 310 | |

| RMG-30A | AUTOMATIC | 220V/380V | 1.5 | 30 粒 pcs / 30-100g | 655x620x1450 | 460 |

| RMG-36A | 220V/380V | 1.5 | 36 粒 pcs / 20-80g | 655x620x1450 | 460 |

Operation of dough ball making machine

1.Switch on the Switch installed on the wall and power switch 58 accordingly,herein Power indication lamp 59 shall be operational.

2.The rolling machine shall be operated without any load, you can check up if any abnormal noise and blockage happens.

3.When new rolling machine operates or it does not operate for long time, please clean up the dust and oily substance on the machine head and rolling plate seat, please commission the machine by 2kg paste repeatedly until machine head and rolling plate seat 3 is cleared up.

4.After machine head and rolling plate seat is cleaned up to produce, please place the paste with better ingredients mixed up at the plastic plate, and then make it smooth and horizontal for suitable time.

5.Place plastic plate into the machine body and on the rolling plate seat 3 (herein one round hole exists on the plastic plate, and rolling cylinder bolt exists on the plate), please confirm if hole and cylinder bolt 4 is aligned better.

6.You need to adjust rolling height before rolling, rolling height shall be adjusted by lined weight adjustment pole 93 at the rolling machine head. Herein, the scale shall be 8 while rolling paste of 80g per piece, scale shall be 5 while of 50g per piece; please lock up the given screw after adjustment. Do not too be big or small while adjustment of their scales. as being too small scale. the rolled paste shall damage its surface shape of the paste, by contrast, if too big scale, the rolled paste shall not be desired.

7.After better adjustment, press down upper machine head and hold up pressed tube 101, herein you can press the paste even and smooth, now the past pressed shall be cut evenly.

8.Left hand pushes away block blade 76, and press pressurized tube 101 in place, evenness of paste mixed up shall directly affect cut even weight and the paste shall be without any bigger uneven bubble accordingly.

9.Slightly release pressurized tube 101(it makes machine head and rolling pleat keeps away from 1mm), left hand slowly presses downward (see arrowhead direction) rolling pole19, and gradually speed up about 3-5s, left hand comes back rolling pole 19, the smaller the past , the longer rolling of the paste, the time of paste rolling shall be different from different products.

10.Release upward pressurized tube 101, and let cut part of machine head separate from the paste and back to original position, takes out the plastic plate, herein one operation is complete.

11.After operation is completed, please switch off red power switch and general power switch installed on the wall, clean up the paste pasted and oily substance, you only can be off work.

Our Service

1.To satisfy one-stop convenience for our client, our company presented service of matching kitchen equipment.

2.We offers OEM & ODM services. Our company has strong ability to design and manufacture, with more than 13 years of business experience.

3.Customized according to the different needs of customers, such as the energy consumption of diesel, electric and gas.

4.We can offer the spare parts according to your order. One year warranty.

5.You have flexibility to choose the payment terms that work best for your budget.

6. We offers profession consultancy and solution to customers.

7. Packed in protective wooden case to ensure the safety of transportation. All our product can be packed as you need.

8.With CE & ISO9001 certification.

8.Factory direct sale price. Quality assurance.

Seng Inquiry To Us

- Product Details

-

Semi automatic dough ball making machine

About R&M semi automatic dough ball making machine

R&M semi automatic dough divider rounder can use as pizza dough rounder machine,bread rounder machine as well as bun rounder. it will be your sincere and best assistant in your bakery shop business.

Specification of dough ball rounder machine

Model TYPE Voltage Power (kw) Specification Size (mm) N.W.(KG) RMG-26S SEMI-AUTO 220V/380V 0.75 26 粒 pcs / 50-140g 670x780x1492 310 RMG-30S 220V/380V 0.75 30 粒 pcs / 30-100g 670x780x1492 310 RMG-36S 220V/380V 0.75 36 粒 pcs / 20-80g 670x780x1492 310 RMG-30A AUTOMATIC 220V/380V 1.5 30 粒 pcs / 30-100g 655x620x1450 460 RMG-36A 220V/380V 1.5 36 粒 pcs / 20-80g 655x620x1450 460 Operation of dough ball making machine

1.Switch on the Switch installed on the wall and power switch 58 accordingly,herein Power indication lamp 59 shall be operational.

2.The rolling machine shall be operated without any load, you can check up if any abnormal noise and blockage happens.

3.When new rolling machine operates or it does not operate for long time, please clean up the dust and oily substance on the machine head and rolling plate seat, please commission the machine by 2kg paste repeatedly until machine head and rolling plate seat 3 is cleared up.

4.After machine head and rolling plate seat is cleaned up to produce, please place the paste with better ingredients mixed up at the plastic plate, and then make it smooth and horizontal for suitable time.

5.Place plastic plate into the machine body and on the rolling plate seat 3 (herein one round hole exists on the plastic plate, and rolling cylinder bolt exists on the plate), please confirm if hole and cylinder bolt 4 is aligned better.

6.You need to adjust rolling height before rolling, rolling height shall be adjusted by lined weight adjustment pole 93 at the rolling machine head. Herein, the scale shall be 8 while rolling paste of 80g per piece, scale shall be 5 while of 50g per piece; please lock up the given screw after adjustment. Do not too be big or small while adjustment of their scales. as being too small scale. the rolled paste shall damage its surface shape of the paste, by contrast, if too big scale, the rolled paste shall not be desired.

7.After better adjustment, press down upper machine head and hold up pressed tube 101, herein you can press the paste even and smooth, now the past pressed shall be cut evenly.

8.Left hand pushes away block blade 76, and press pressurized tube 101 in place, evenness of paste mixed up shall directly affect cut even weight and the paste shall be without any bigger uneven bubble accordingly.

9.Slightly release pressurized tube 101(it makes machine head and rolling pleat keeps away from 1mm), left hand slowly presses downward (see arrowhead direction) rolling pole19, and gradually speed up about 3-5s, left hand comes back rolling pole 19, the smaller the past , the longer rolling of the paste, the time of paste rolling shall be different from different products.

10.Release upward pressurized tube 101, and let cut part of machine head separate from the paste and back to original position, takes out the plastic plate, herein one operation is complete.

11.After operation is completed, please switch off red power switch and general power switch installed on the wall, clean up the paste pasted and oily substance, you only can be off work.

- Service

-

Our Service

1.To satisfy one-stop convenience for our client, our company presented service of matching kitchen equipment.

2.We offers OEM & ODM services. Our company has strong ability to design and manufacture, with more than 13 years of business experience.

3.Customized according to the different needs of customers, such as the energy consumption of diesel, electric and gas.

4.We can offer the spare parts according to your order. One year warranty.

5.You have flexibility to choose the payment terms that work best for your budget.

6. We offers profession consultancy and solution to customers.

7. Packed in protective wooden case to ensure the safety of transportation. All our product can be packed as you need.

8.With CE & ISO9001 certification.

8.Factory direct sale price. Quality assurance. - Contact

-

Seng Inquiry To Us