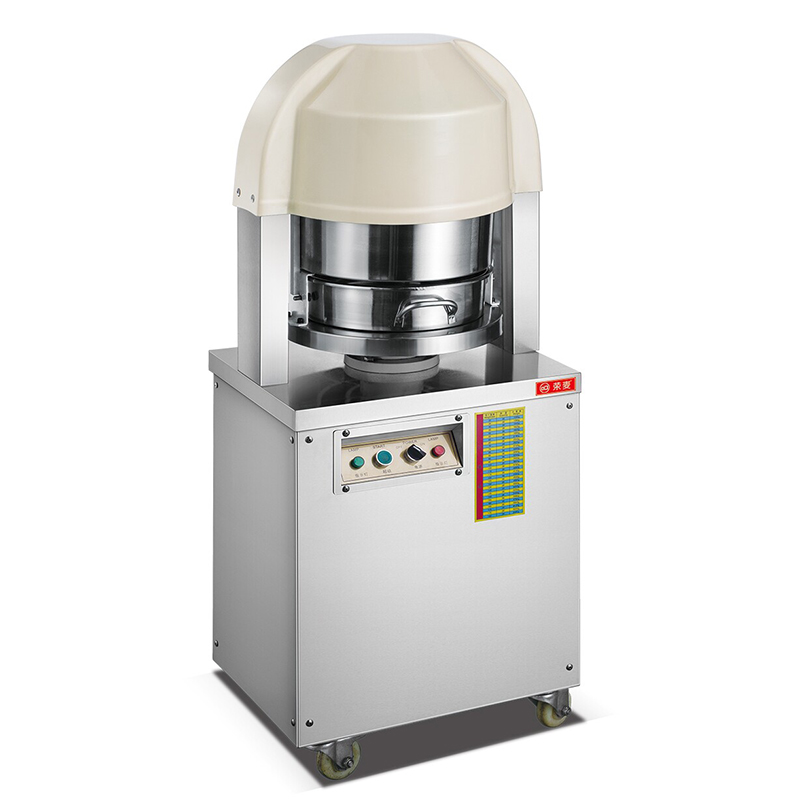

Bakery Equipment For Sale Bread Dough Toast Moudler Machine

1.Perfect for the degassing and shape repairing of bread such as toast, hot-dog and French roll

2.Operating is simply switching “On-Off” push button with only one person

- Unique design . lower noise, not easy to tear and wear ,enhance the service life of machine

4.Special material of pressure rollers which prevents sticking and difficult to scratch and damage.

- High work speed , exhaust sufficiently, it can get the most length of the dough without bubble

Bread dough Toast Moudler machine

Function & Features of bakery Toast Moudler

Toast Moudler Can be used to make various breads and pastries in special patterns as well as to roll or squeeze the dough for expelling air bubbles so as to ensure excellent moisturization effect.

Main Features

With specially-designed structure, the said machine is capable of pulling the dough long enough to deair and enhance dough shear;

The said machine is powerful, fast and can adjust the thickness of dough that is processed;

Once being processed, the dough can roll 2.5~3 cycles that is 1 cycle more than that being processed by other forming machines;

The roller is clad with hard chromium that is able to sustain scratches and create a non-stick surface;

Able to improve the production efficiency considerably and also lower down the manpower cost.

Advantsges of Bread dough moudler

1.Perfect for the degassing and shape repairing of bread such as toast, hot-dog and French roll

2.Operating is simply switching “On-Off” push button with only one person

- Unique design . lower noise, not easy to tear and wear ,enhance the service life of machine

4.Special material of pressure rollers which prevents sticking and difficult to scratch and damage.

- High work speed , exhaust sufficiently, it can get the most length of the dough without bubbl

Main Parameters

Voltage: (1) Single Phase220V~50-60HZ~0.75KW

(2) 3-phase 380V~50HZ~0.75KW

Please specify one model while placing an order and it is recommended to adopt the 3-phase 380V model in order to conserve energy and lower down noise.

Dimensions: 500×1050×1300

Weight: 210kg

Operation Width: 380mm

| Model | TYPE | Voltage | Power (kw) | Capacity | Size(mm) | Weigh |

| RMZ-380 | Toast Moulder | 220/380V | 0.75 | 1000-3000 pcs/h | 665x1500x1180 | 225 |

Operation Description of Toast Moudler machine

The small wheel on the top is used to adjust the width of the feeding opening and should be locked following adjustment. The width of the feeding opening should be sufficient for a dough to get through and if too wide, waste could be resulted in as the dough exceeds the rolling surface.

Those 2 large wheels behind are used to adjust the gap for the upper and lower roller sets so as to obtain dough with proper shear and in proper forms. In the process of adjustment, increase the spacing for the upper rollers and decrease for the lower rollers. Through this way, the dough can be rolled down and extended twice.

The tension of the forming stainless steel mesh is adjustable. To obtain obvious forming effects, loosen the mesh and to eliminate influences, tighten the mesh. When pressing a dough independently, take out the forming mesh.

The forming board attached to the suspension arm can be lifted and lowered via a wheel and the special patterned plastic board at the bottom is used to squeeze the dough. Adjust both components according to the product requirements. When pressing a dough independently, lift the forming board.

The frame above the conveyor belt can be used to load materials so as to save space. It is also conducive for operation.

A retractable board that can be pulled out to catch dough falling from the conveyer belt is attached.

Cautions:

As the rollers are rotating at high speed, it is forbidden to reach out hands into the feeding opening during operation. Additionally, lower down the protection hood and disconnect the power supply while maintaining the machine.

Never feed hard object into the machine via the feeding opening and the dough to be rolled should not be too hard. It is forbidden to accept the frozen dough before thaw. Otherwise, the machine’s service life could be impaired.

Following operation each day, clean up the conveyer belt and the surface of the rollers as well. Remove the dough residual stuck to both ends of the rollers timely as once it enters the rolling bearing, unexpected maintenance loss could be incurred.

Form such a good habit that to test the machine before operation to check out for irregular noise. If any fault is detected, take relevant actions immediately so as to prevent life and machine damages even caused by a loose bolt or other small irregularities.

Although it is easy to operate the said machine, operators without receiving any relevant training programs should not be allowed to work with it as it is always necessary to obtain knowledge about operation key points and safety issues before operation through training for any kind of machine.

Be aware of the rotation direction of the rollers while connecting cables.

Our Service

1.To satisfy one-stop convenience for our client, our company presented service of matching kitchen equipment.

2.We offers OEM & ODM services. Our company has strong ability to design and manufacture, with more than 13 years of business experience.

3.Customized according to the different needs of customers, such as the energy consumption of diesel, electric and gas.

4.We can offer the spare parts according to your order. One year warranty.

5.You have flexibility to choose the payment terms that work best for your budget.

6. We offers profession consultancy and solution to customers.

7. Packed in protective wooden case to ensure the safety of transportation. All our product can be packed as you need.

8.With CE & ISO9001 certification.

8.Factory direct sale price. Quality assurance.

Seng Inquiry To Us

- Product Details

-

Bread dough Toast Moudler machine

Function & Features of bakery Toast Moudler

Toast Moudler Can be used to make various breads and pastries in special patterns as well as to roll or squeeze the dough for expelling air bubbles so as to ensure excellent moisturization effect.

Main Features

With specially-designed structure, the said machine is capable of pulling the dough long enough to deair and enhance dough shear;

The said machine is powerful, fast and can adjust the thickness of dough that is processed;

Once being processed, the dough can roll 2.5~3 cycles that is 1 cycle more than that being processed by other forming machines;

The roller is clad with hard chromium that is able to sustain scratches and create a non-stick surface;

Able to improve the production efficiency considerably and also lower down the manpower cost.

Advantsges of Bread dough moudler

1.Perfect for the degassing and shape repairing of bread such as toast, hot-dog and French roll

2.Operating is simply switching “On-Off” push button with only one person

- Unique design . lower noise, not easy to tear and wear ,enhance the service life of machine

4.Special material of pressure rollers which prevents sticking and difficult to scratch and damage.

- High work speed , exhaust sufficiently, it can get the most length of the dough without bubbl

Main Parameters

Voltage: (1) Single Phase220V~50-60HZ~0.75KW

(2) 3-phase 380V~50HZ~0.75KW

Please specify one model while placing an order and it is recommended to adopt the 3-phase 380V model in order to conserve energy and lower down noise.

Dimensions: 500×1050×1300

Weight: 210kg

Operation Width: 380mm

Model TYPE Voltage Power (kw) Capacity Size(mm) Weigh RMZ-380 Toast Moulder 220/380V 0.75 1000-3000 pcs/h 665x1500x1180 225 Operation Description of Toast Moudler machine

The small wheel on the top is used to adjust the width of the feeding opening and should be locked following adjustment. The width of the feeding opening should be sufficient for a dough to get through and if too wide, waste could be resulted in as the dough exceeds the rolling surface.

Those 2 large wheels behind are used to adjust the gap for the upper and lower roller sets so as to obtain dough with proper shear and in proper forms. In the process of adjustment, increase the spacing for the upper rollers and decrease for the lower rollers. Through this way, the dough can be rolled down and extended twice.

The tension of the forming stainless steel mesh is adjustable. To obtain obvious forming effects, loosen the mesh and to eliminate influences, tighten the mesh. When pressing a dough independently, take out the forming mesh.

The forming board attached to the suspension arm can be lifted and lowered via a wheel and the special patterned plastic board at the bottom is used to squeeze the dough. Adjust both components according to the product requirements. When pressing a dough independently, lift the forming board.

The frame above the conveyor belt can be used to load materials so as to save space. It is also conducive for operation.

A retractable board that can be pulled out to catch dough falling from the conveyer belt is attached.

Cautions:

As the rollers are rotating at high speed, it is forbidden to reach out hands into the feeding opening during operation. Additionally, lower down the protection hood and disconnect the power supply while maintaining the machine.

Never feed hard object into the machine via the feeding opening and the dough to be rolled should not be too hard. It is forbidden to accept the frozen dough before thaw. Otherwise, the machine’s service life could be impaired.

Following operation each day, clean up the conveyer belt and the surface of the rollers as well. Remove the dough residual stuck to both ends of the rollers timely as once it enters the rolling bearing, unexpected maintenance loss could be incurred.

Form such a good habit that to test the machine before operation to check out for irregular noise. If any fault is detected, take relevant actions immediately so as to prevent life and machine damages even caused by a loose bolt or other small irregularities.

Although it is easy to operate the said machine, operators without receiving any relevant training programs should not be allowed to work with it as it is always necessary to obtain knowledge about operation key points and safety issues before operation through training for any kind of machine.

Be aware of the rotation direction of the rollers while connecting cables.

- Service

-

Our Service

1.To satisfy one-stop convenience for our client, our company presented service of matching kitchen equipment.

2.We offers OEM & ODM services. Our company has strong ability to design and manufacture, with more than 13 years of business experience.

3.Customized according to the different needs of customers, such as the energy consumption of diesel, electric and gas.

4.We can offer the spare parts according to your order. One year warranty.

5.You have flexibility to choose the payment terms that work best for your budget.

6. We offers profession consultancy and solution to customers.

7. Packed in protective wooden case to ensure the safety of transportation. All our product can be packed as you need.

8.With CE & ISO9001 certification.

8.Factory direct sale price. Quality assurance. - Contact

-

Seng Inquiry To Us