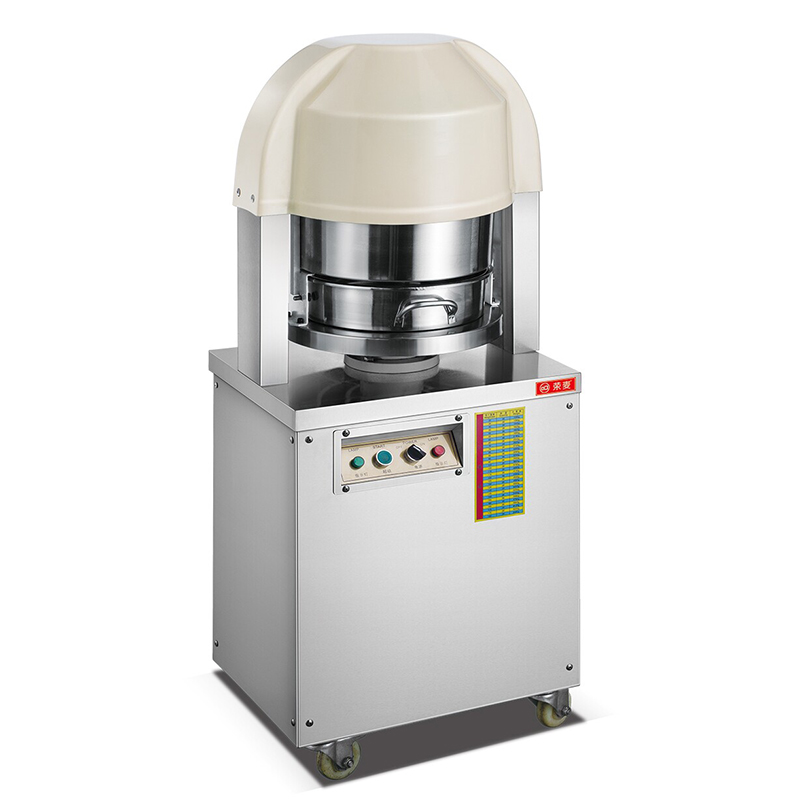

Automatic Dough Divider Rounder For Sale Bakery Machine Price

- Please use the forklift removed the machine to the proper place and then dismantled the box.

- After dismantled it, please check the name, model, number, the quantity of fittings is harmonious with the Packing list,Certificate of eligibility,Warranty. If you has any question, please contact with us.

- Connecting the wall air switch with the cable then turn on the machine, the direction is converse (as the arrowhead). It is completely installation if has no abnormal noise or can normal working.

« It is must to connect with the floor safe.

« If need to replace the cable, please use the cable which is not lighter than the common neoprene or others synthetic rubber. It is not shorter than 3m.

Commercial dough divider rounder machine

About R&M commercial dough divider rounder machine

R&M automatic dough divider rounder will be your sincere and best assistant in your baking business career. Please waiting for about 15-20 minutes after dough fermenting, then begin dividing and rounding it will be get good effect.The dough divider & dough rounder machine has the function that it can complete and uniform cutting.The model, specification and the parameter as follows:

Specification of automatic dough divider rounder machine

| Model | TYPE | Voltage | Power(kw) | Specification | Size (mm) | N.W.(KG) |

| RMG-26S | SEMI-AUTO | 220V/380V | 0.75 | 26 pcs / 50-140g | 670x780x1492 | 310 |

| RMG-30S | 220V/380V | 0.75 | 30 pcs / 30-100g | 670x780x1492 | 310 | |

| RMG-36S | 220V/380V | 0.75 | 36 pcs / 20-80g | 670x780x1492 | 310 | |

| RMG-30A | AUTOMATIC | 220V/380V | 1.5 | 30 pcs / 30-100g | 655x620x1450 | 460 |

| RMG-36A | 220V/380V | 1.5 | 36 pcs / 20-80g | 655x620x1450 | 460 |

Removal and Installation of dough divider rounder machine

- Please use the forklift removed the machine to the proper place and then dismantled the box.

- After dismantled it, please check the name, model, number, the quantity of fittings is harmonious with the Packing list,Certificate of eligibility,Warranty. If you has any question, please contact with us.

- Connecting the wall air switch with the cable then turn on the machine, the direction is converse (as the arrowhead). It is completely installation if has no abnormal noise or can normal working.

« It is must to connect with the floor safe.

« If need to replace the cable, please use the cable which is not lighter than the common neoprene or others synthetic rubber. It is not shorter than 3m.

Operation Direction of automatic dough divider rounder machine

- Turn on the air switch and the power, the light will bright.

- Working with empty, and to check there has any noise and block phenomenon or not.

- Please cleaning the dust of the machine and the plate before turn on the new machine or unused for a long time. And repeat to text the machine with the paste about 2kg, until there are cleaned.

- Please put the paste in the plastic plate which is mixed according to the prescription, and slack for a while.

- Put the plate which has the paste into the roll plate (there is a aperture and a column pin), please make sure the aperture is aim at the column pin or not.

- Please adjust the height before working, and the height is controlled by the weight adjusting handle which has the figure. Don’t adjust the scale too big or too small, too small scale will damage the smooth of the dough, too big will affect the rounder effect.

- Set the rounding time. Usually is about 4 seconds, according the dough need to set the time.

- Turn the handle40 to right with the left hand, and compact the push down the pressurize tube.

- Flab the pressurize tube15 (make the machine head away from the plate about 1mm), then shelve the roll handle26 to the right lower part, and expedite the speed gradually for 3-5 seconds. The paste is smaller, the time is longer.

- Replaced the pressurize tube, and make the partition component take off the paste, and then take out the plate. And the operation is finished.

- Please close the red Power and the air switch and cleaning it when unused.

«It designed for drip-proof structure, when clean it please don’t use the spray pipe.

Maintenance instruction of automatic dough divider rounder machine

- The ways of cleaning as follows:

- a) Turn off the Power, and cleaning the blade, plate, etc. With the brush.

- b) Put down the machine head and flab the pressurize tube after cleaned.

- c) Forelock the pin.

d). After operate it please clean the plate, in case the food molding or corroding the machine.

- Maintenance

- a) Keep the machine head lubricities. And please use the Food Oil.

- b) Please check the slippage axes pedestal every 3 months or found there is leakage. Please add the 32# lube when it lower the 1cm, and not exceed to 2cm.

- c) Please check the delivery belt is flab or not every 30 work days(10 work days of new machine), or when the operation is slowly. If it is too flab, you can slack the motor to stable the bolt, and adjust the motor to the moderate place, then stable it.

- Attention

- a) Please do not use, maintain, cleaned the machine without read and understand the manual.

- b) Please use the Food Oil to lubricate the machine.

- c) Please cut off the power when maintain or cleaned.

- d) Do not make any violence action to destroy the machine.

- e) Do not touch with the paint when the machine is working, to avoid the paint fall into the paste.

- f) Please clean the food sediments when cleaning.

- g) Please dried the cleaned plate to the ventilated place. And do not bake, freeze it, to avoid distortion.

- h) Please clean the machine head, dust, etc. Before use the new machine or unused it for a long time.

Our Service

1.To satisfy one-stop convenience for our client, our company presented service of matching kitchen equipment.

2.We offers OEM & ODM services. Our company has strong ability to design and manufacture, with more than 13 years of business experience.

3.Customized according to the different needs of customers, such as the energy consumption of diesel, electric and gas.

4.We can offer the spare parts according to your order. One year warranty.

5.You have flexibility to choose the payment terms that work best for your budget.

6. We offers profession consultancy and solution to customers.

7. Packed in protective wooden case to ensure the safety of transportation. All our product can be packed as you need.

8.With CE & ISO9001 certification.

8.Factory direct sale price. Quality assurance.

Seng Inquiry To Us

- Product Details

-

Commercial dough divider rounder machine

About R&M commercial dough divider rounder machine

R&M automatic dough divider rounder will be your sincere and best assistant in your baking business career. Please waiting for about 15-20 minutes after dough fermenting, then begin dividing and rounding it will be get good effect.The dough divider & dough rounder machine has the function that it can complete and uniform cutting.The model, specification and the parameter as follows:

Specification of automatic dough divider rounder machine

Model TYPE Voltage Power(kw) Specification Size (mm) N.W.(KG) RMG-26S SEMI-AUTO 220V/380V 0.75 26 pcs / 50-140g 670x780x1492 310 RMG-30S 220V/380V 0.75 30 pcs / 30-100g 670x780x1492 310 RMG-36S 220V/380V 0.75 36 pcs / 20-80g 670x780x1492 310 RMG-30A AUTOMATIC 220V/380V 1.5 30 pcs / 30-100g 655x620x1450 460 RMG-36A 220V/380V 1.5 36 pcs / 20-80g 655x620x1450 460 Removal and Installation of dough divider rounder machine

- Please use the forklift removed the machine to the proper place and then dismantled the box.

- After dismantled it, please check the name, model, number, the quantity of fittings is harmonious with the Packing list,Certificate of eligibility,Warranty. If you has any question, please contact with us.

- Connecting the wall air switch with the cable then turn on the machine, the direction is converse (as the arrowhead). It is completely installation if has no abnormal noise or can normal working.

« It is must to connect with the floor safe.

« If need to replace the cable, please use the cable which is not lighter than the common neoprene or others synthetic rubber. It is not shorter than 3m.

Operation Direction of automatic dough divider rounder machine

- Turn on the air switch and the power, the light will bright.

- Working with empty, and to check there has any noise and block phenomenon or not.

- Please cleaning the dust of the machine and the plate before turn on the new machine or unused for a long time. And repeat to text the machine with the paste about 2kg, until there are cleaned.

- Please put the paste in the plastic plate which is mixed according to the prescription, and slack for a while.

- Put the plate which has the paste into the roll plate (there is a aperture and a column pin), please make sure the aperture is aim at the column pin or not.

- Please adjust the height before working, and the height is controlled by the weight adjusting handle which has the figure. Don’t adjust the scale too big or too small, too small scale will damage the smooth of the dough, too big will affect the rounder effect.

- Set the rounding time. Usually is about 4 seconds, according the dough need to set the time.

- Turn the handle40 to right with the left hand, and compact the push down the pressurize tube.

- Flab the pressurize tube15 (make the machine head away from the plate about 1mm), then shelve the roll handle26 to the right lower part, and expedite the speed gradually for 3-5 seconds. The paste is smaller, the time is longer.

- Replaced the pressurize tube, and make the partition component take off the paste, and then take out the plate. And the operation is finished.

- Please close the red Power and the air switch and cleaning it when unused.

«It designed for drip-proof structure, when clean it please don’t use the spray pipe.

Maintenance instruction of automatic dough divider rounder machine

- The ways of cleaning as follows:

- a) Turn off the Power, and cleaning the blade, plate, etc. With the brush.

- b) Put down the machine head and flab the pressurize tube after cleaned.

- c) Forelock the pin.

d). After operate it please clean the plate, in case the food molding or corroding the machine.

- Maintenance

- a) Keep the machine head lubricities. And please use the Food Oil.

- b) Please check the slippage axes pedestal every 3 months or found there is leakage. Please add the 32# lube when it lower the 1cm, and not exceed to 2cm.

- c) Please check the delivery belt is flab or not every 30 work days(10 work days of new machine), or when the operation is slowly. If it is too flab, you can slack the motor to stable the bolt, and adjust the motor to the moderate place, then stable it.

- Attention

- a) Please do not use, maintain, cleaned the machine without read and understand the manual.

- b) Please use the Food Oil to lubricate the machine.

- c) Please cut off the power when maintain or cleaned.

- d) Do not make any violence action to destroy the machine.

- e) Do not touch with the paint when the machine is working, to avoid the paint fall into the paste.

- f) Please clean the food sediments when cleaning.

- g) Please dried the cleaned plate to the ventilated place. And do not bake, freeze it, to avoid distortion.

- h) Please clean the machine head, dust, etc. Before use the new machine or unused it for a long time.

- Service

-

Our Service

1.To satisfy one-stop convenience for our client, our company presented service of matching kitchen equipment.

2.We offers OEM & ODM services. Our company has strong ability to design and manufacture, with more than 13 years of business experience.

3.Customized according to the different needs of customers, such as the energy consumption of diesel, electric and gas.

4.We can offer the spare parts according to your order. One year warranty.

5.You have flexibility to choose the payment terms that work best for your budget.

6. We offers profession consultancy and solution to customers.

7. Packed in protective wooden case to ensure the safety of transportation. All our product can be packed as you need.

8.With CE & ISO9001 certification.

8.Factory direct sale price. Quality assurance. - Contact

-

Seng Inquiry To Us